Our custom sheet metal fabrication uses manufacturing processes to shape pieces of metal into the desired product using cutting, bending, welding and assembly processes. Our team works with customers to create parts that range from small plates and brackets to large racks and enclosures.

We work with customers so that we understand your application and requirements, so that the parts we deliver meet your needs for production and beyond. Our team has decades of experience to bring insight into the best material, hardware, and production method to meet your needs.

Material (thickness: .006” to .375”):

- Aluminum

- Stainless steel

- Cold and hot-rolled steel

- Copper

- Brass

Small Parts

Our precision equipment and experienced team works with customers to manufacture small parts that are integral to an overall design.

These parts include brackets, washers, plates, and connectors among others.

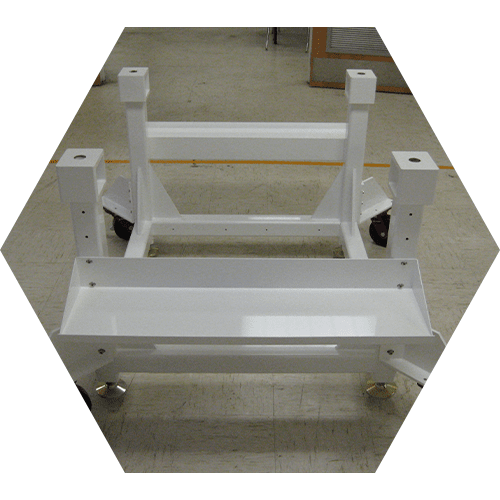

Big Parts

Our 43,000 square foot facility and large scale equipment enables us to work with customers on large parts such as plates, doors, panels, light boxes and others.

Our dedicated team of welders and production staff work together to build high quality frames, racks and carts that last and stand up to regular wear and tear.

Our customers for these products include industrial laser, animal testing, and food service companies. Our 43,000 square foot facility means that we have the dedicated space to build, assemble and test these often very large parts.

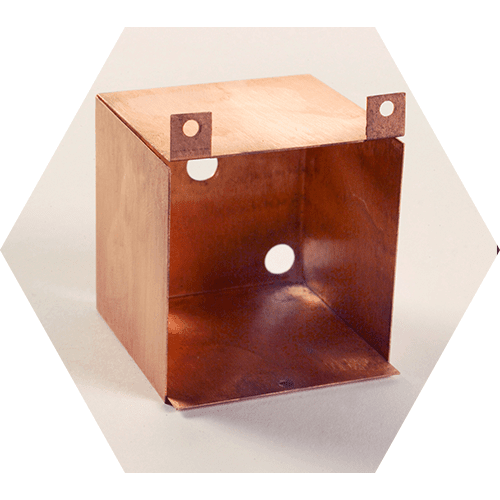

Enclosures

Enclosures are critical to safeguarding the tooling, electronics and equipment manufactured by many of our customers.

Our team ensures that the enclosures we manufacture provide the protection required of your equipment and, as importantly, provide a great reflection of your brand and quality to your customers.