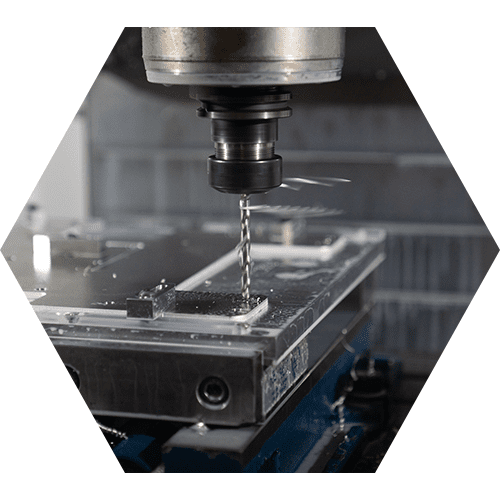

ETM started more than 50 years ago as a machine shop. Today, our machine shop capabilities address customers’ need to consolidate suppliers. Why worry about managing a machine shop and a sheet metal shop when you can achieve your requirements with a single supplier?

We have 4 modern 3 axis CNC Vertical Milling machines that allow us to work with customers to make precision machined parts to meet their production and prototyping needs. Machining allows us to make parts that require thick material and complex shapes that are difficult if not impossible to produce using our typical sheet metal fabrication processes.

At ETM, precision machining is routine. We specialize in holding 0.005″ tolerance in a 30″ length or .0002″ tolerances on size and location of holes in aluminum guide rails, as well as accurate machining of a variety of materials including aluminum, steel, stainless steel, PVC and more. This is made possible through the use of the latest CNC controlled equipment and CAD/CAM software.

Design control can be assured with a direct upload from our customer’s files, and our CNC vertical mills provide accuracy, repeatability and reliability.